PRODUCTS

BT2K 600 PLUS

ADVANTAGES

•Fast and easy to apply

•Applicable to all mineral surfaces

•High flexibility and capacity of crack bridging.

•It is resistant to microorganism and aggressive underground water.

•Creates flexible, covering and continuous insulation layer in vertical and horizontal grounds, dry and mildly damp surfaces.

•It is environmentally-friendly as it is water-based. It can be used outdoors easily

•Owing to excellence adherence, breaking or swelling problems are not observed.

PLACES OF USE

- As the water and moisture proofing material in underground applications such as foundation, curtain wall and basement

- To protect and insulate the structure and building members exposed to continuous and temporary water pressure, seepage water

- As waterproofing materials in roof, kitchen, bathroom, etc, dry or mildly damp details

- For insulating mineral surfaces such as concrete, stone, briquet, plaster, screed, etc.

- Repair of old bituminous membrane, asphalt, etc. insulation

- Adhering thermal insulating board

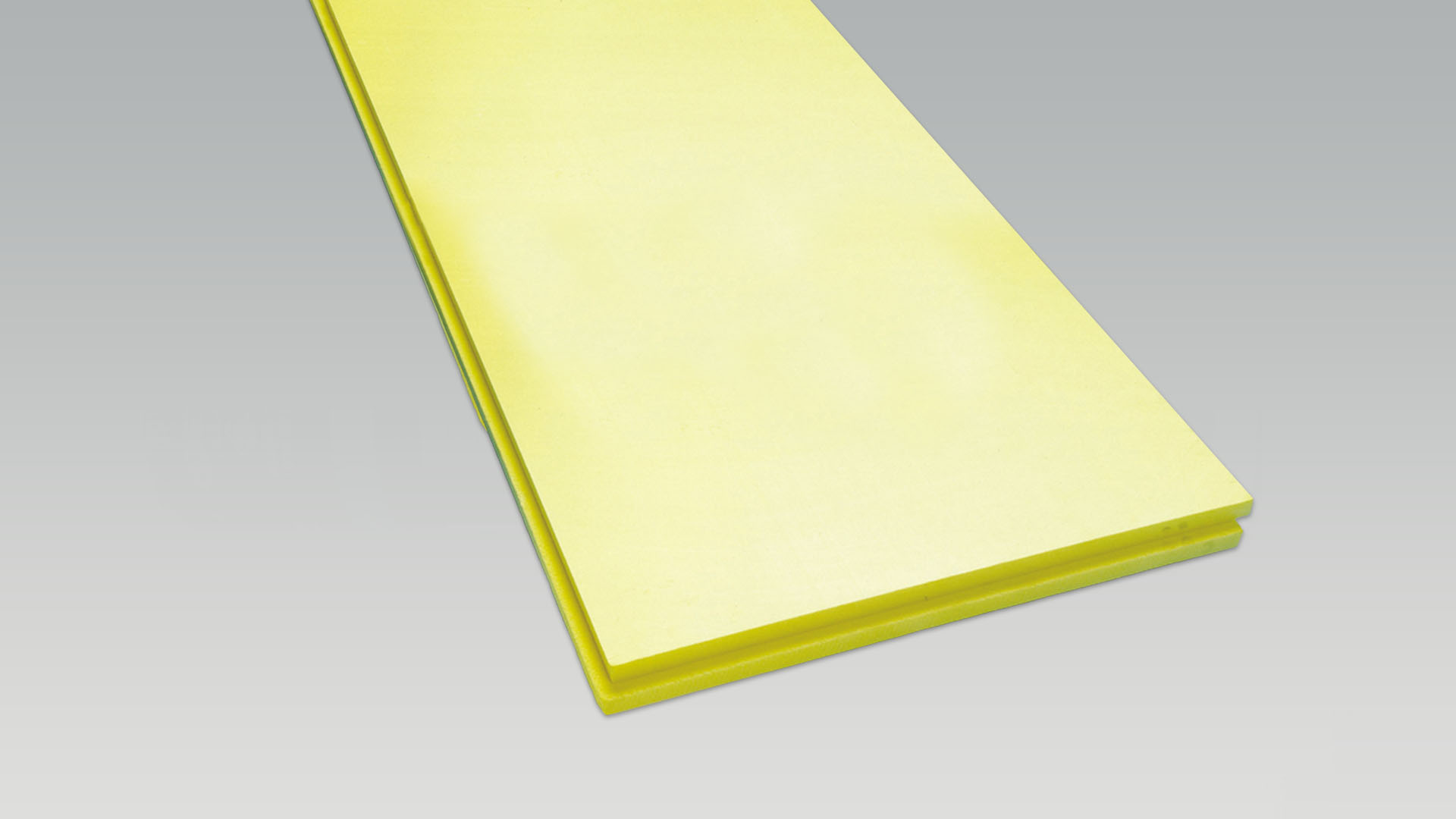

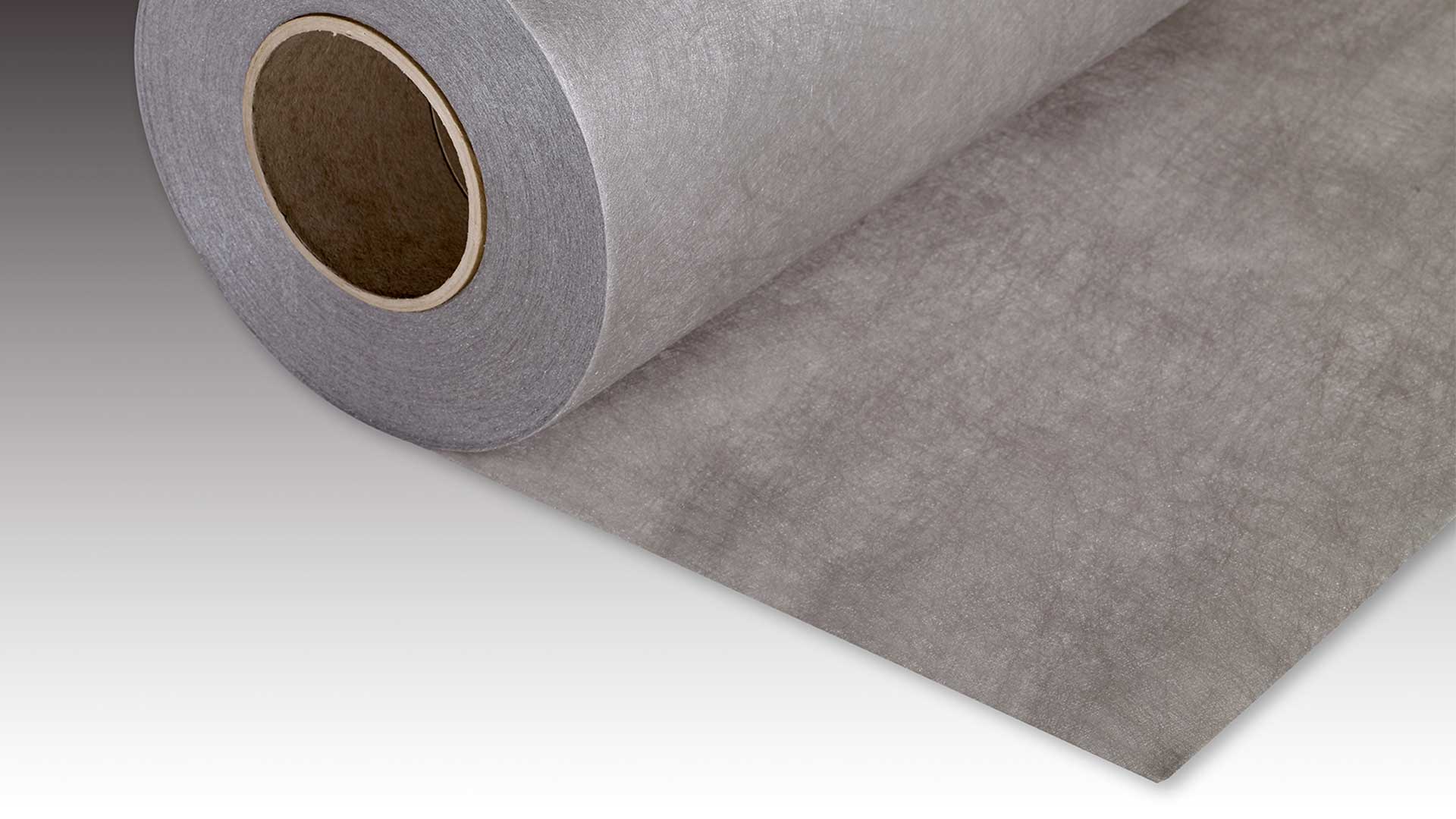

- Insulation applications requiring to be resistant to higher pressure water with insulation mesh (alkali resistant glass-fiber mesh (145 gr/m²), non-woven polyester felt, isolation cloth

TECHNICAL SPECIFICATIONS

- Base: Polymer modified bitumen rubber

- Liquid component: Polymer bitumen dispersion

- Powder component: powder mixture with special filler and chemical additive

- Color: Black

- Form: pasty viscous liquid

- Density: appx. 1,1 kg/l

- Heat resistance: 100 ˚C

- Post-curing water tightness (DIN 1048): 7 bar

- Watertightness: Impermeable in accordance with EN 15820 W1 class (0,075 bar).

- Solid matter percent of the mixture: ≤%80

- Workability time: 1-2 hours *

- Drying time: min. 24 hours*

- Complete drying time: 3 days*

* depends on temperature and relative moisture rate

SURFACE PREPARATION

The surface should be cleaned from dust, dirt, rust and oil, loose particles. Sharp ends and corners should be rounded. Iron and wooden wedges on the application surface should be removed and active water leak and gaps if any should be filled with Elastopast or Elastomast. Minimum 4 cm in diameter beveling should be applied to the corner and edges. Ruined and eyelet hole surfaces should be smoothened and covered by mortar scraping. Defects larger than 5 mm on the surface and rod holes on curtain walls should be filled in and repaired with proper repair mortar. If there is water, water vapor and efflorescence on the negative side, the application should not be performed on such surface. Surface roughening should be applied to increase adherence in extremely impermeable (high resistance class) concrete and curtain walls to increase adherence.

APPLICATION

Application ambient temperature: +5 ˚C / +35 ˚C •Application surface temperature: +5 ˚C / +30˚C • Mixing: Mixing quantity: 24 kg liquid component 8 kg powder component • Powder component is added to liquid component slowly and mixed for 3-5 min with 400-600 rev/mi mixer until homogenous and smooth mixture is obtained. Material mixed should be consumed within 1-2 hours.

Prime application: Surfaces; It is diluted as in the ratio of 1/1 to 1 / 2 (Bitümer BTR 200 / water) or BT2K 500 A+B mixture with up to 30% water and applied as the prime. *Ratio of dilution with water should be adjusted by the surface absorption. Coating application: After the prime coat dries, it s applied with a brush, roller or trowel or proper spraying equipment in the thickness of 2-6 mm. It may be applied more based on the water pressure that the waterproofing layer will be exposed to and roughness and absorption of the surface. If it is applied as two coats, the first coat should cure and then other coat should be applied. In wide areas, it is recommended to be used with 145 g/m² fiber reinforcement for bridging cracks and increasing mechanical properties in the vertical-horizontal joints. Mixture prepared should be consumed within 1-2 hours. Application tools should be cleaned with water immediately after the application. Tools not cleaned in time can be cleaned with thinner later.

CONSUMPTION

It varies by the condition of application surface and water pressure that the insulation layer will be exposed to; For moisture resistant insulation: 3 mm thickness min. 3,3kg/m². For non-pressure water resistance: 4 mm thickness min. 4.4kg/m² For pressure water resistance: 6 mm thickness min. 6.6 kg/m² For adhering thermal insulating board: min. 2 kg/m²

PACKAGING

Liquid and powder components 32 kg plastic bucket (Liquid; 24 kg, powder; 8 kg)

STORAGE CONDITION AND SHELFLIFE

It should be stored in a dry area and protected against sun and frost. The product will freeze at temperature below 0°C. shelf life is 12 months in the original unsealed packaging and under proper storage conditions.

![]() BTM Bitümlü Tecrit Maddeleri Sanayi ve Ticaret A.Ş. Kemalpaşa O.S.B. Mahallesi Gazi Bulvarı No:152 35730 Kemalpaşa/İzmir TURKEY Phone:+90 232 877 04 02 Fax:+90 232 877 04 10 info@btm.co • www.btm.co

BTM Bitümlü Tecrit Maddeleri Sanayi ve Ticaret A.Ş. Kemalpaşa O.S.B. Mahallesi Gazi Bulvarı No:152 35730 Kemalpaşa/İzmir TURKEY Phone:+90 232 877 04 02 Fax:+90 232 877 04 10 info@btm.co • www.btm.co